Alexandros S. Kalafatelis and Angeliki Krikella

Four Dot Infinity

In CyclOps Use Case 4 (UC4), Four Dot Infinity (FDI), Pressious Arvanitidis S.A., Colorprint S.A., and the Centre for Research & Technology Hellas (CERTH) are working together to build a Manufacturing Data Space (MDS) for the offset printing industry. The aim is straightforward: help factories make better use of the data they already generate every day, without creating new burdens for the people who run production.

Offset printing lines produce a steady stream of information, i.e., machine signals, production settings, quality checks, maintenance notes, and job-related parameters. In many plants, however, that information ends up split across different systems, stored in different formats, and used mainly for troubleshooting after the fact. UC4 focuses on changing that. The goal is to turn scattered operational data into something that supports day-to-day decisions on the shop floor: earlier warnings when equipment starts drifting from normal behaviour, fewer unplanned stops, better scheduling, and more predictable output.

This matters because the sector is operating under real pressure. Energy and material costs continue to rise, lead times are tighter, and customers expect consistent quality with less waste. Data-driven methods can help, but only when companies can analyze and share insights without exposing sensitive production information or losing control over how their data is used. That is exactly the gap UC4 is designed to address: enable collaboration and learning across sites, while keeping data ownership and confidentiality intact. Toward this, two techniques are central to the AI work in UC4: Federated Learning and Transfer Learning.

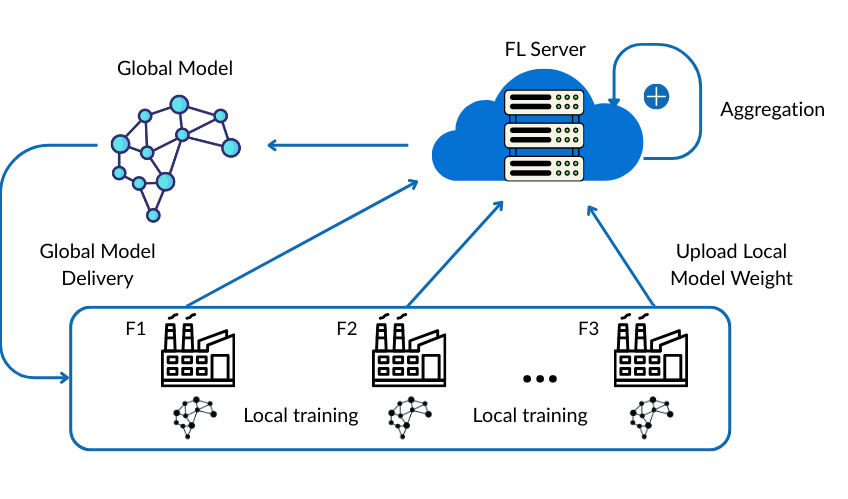

Federated Learning (FL) allows multiple organizations to train a shared machine-learning model without moving their raw data to a central repository. Instead, each factory trains the model locally on its own systems. Only the resulting model updates are shared and combined, while the underlying operational data stays on-site. In an industrial context, this is not a “nice to have”. Production data can reveal process know-how, operating limits, and business-sensitive patterns that companies cannot simply hand over, even to trusted partners. FL creates a practical path to collaboration by keeping the data where it belongs, while still allowing the model to learn from a wider range of real operating conditions.

Figure 1: FL framework adapted for the manufactory domain

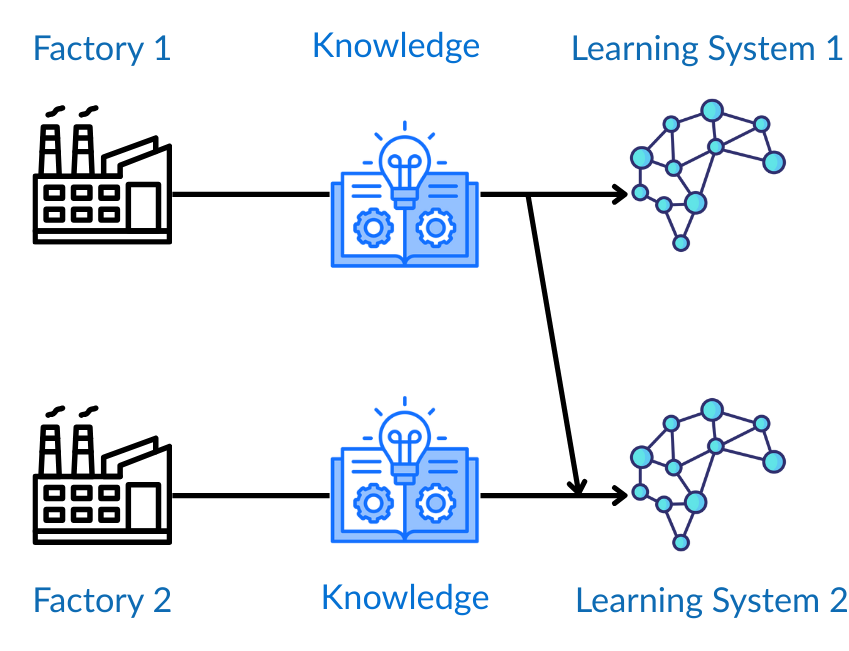

Transfer Learning (TL) tackles a different, equally common challenge: how to build reliable models when data is limited, imbalanced, or not perfectly comparable across machines. In UC4, both pilot companies operate Heidelberg printers. The machines may come from the same manufacturer and export similar variables, but the reality on the ground is that behaviour differs across models, workloads, maintenance practices, and operating regimes. One printer might show repeated degradation patterns in a specific subsystem, while another exhibits a different “signature” under similar production demands. Transfer Learning helps by taking what a model has already learned on one machine or setting and adapting it to another, rather than starting from scratch every time.

Figure 2: Transfer learning process

This brings practical benefits for predictive maintenance. It reduces the amount of new data needed to reach a useful level of accuracy, shortens training cycles, and supports faster deployment. It also helps when certain faults are rare (which is good for production, but difficult for model training), because knowledge from a related machine can improve early detection even when failure examples are scarce.

The value in UC4 comes from combining these two approaches. With Federated Learning, each factory can train on its own operational reality while staying in control of its data. With Transfer Learning, the resulting models can be adapted across different printer models or site-specific conditions without long re-training periods. Together, they support a balanced outcome, collaboration without data exposure, and models that can cope with the differences that exist between real factories and real machines.

The Manufacturing Data Space is the foundation that makes this feasible in practice. It is not just about “connecting systems”; it is about enabling secure participation and controlled exchange of information and services, so that each organization can decide what is shared, with whom, and under what conditions. For the offset printing sector, this translates into more reliable equipment availability through predictive maintenance, better planning decisions, reduced material waste, and incremental improvements that add up over time.

UC4 is also intended as a blueprint beyond printing. Many manufacturing domains face the same mix of challenges, i.e., fragmented data, high sensitivity of operational information, and a need to improve performance without introducing new risks. By showing how factories can learn from each other while keeping their data local and protected, UC4 demonstrates a realistic path toward trustworthy industrial AI built on data spaces.